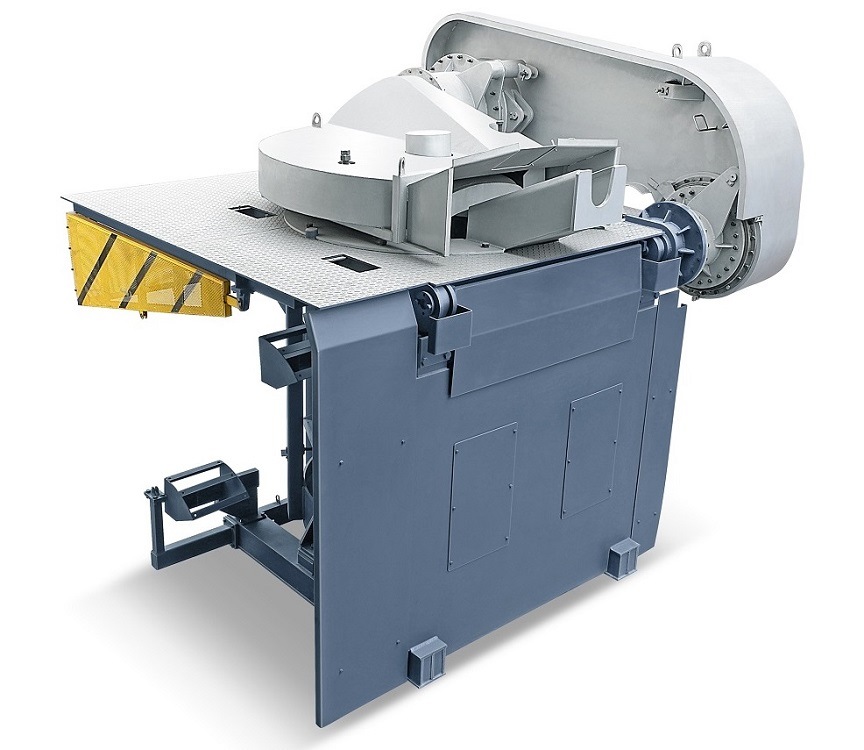

Steel shell furnace

Furnace Features:

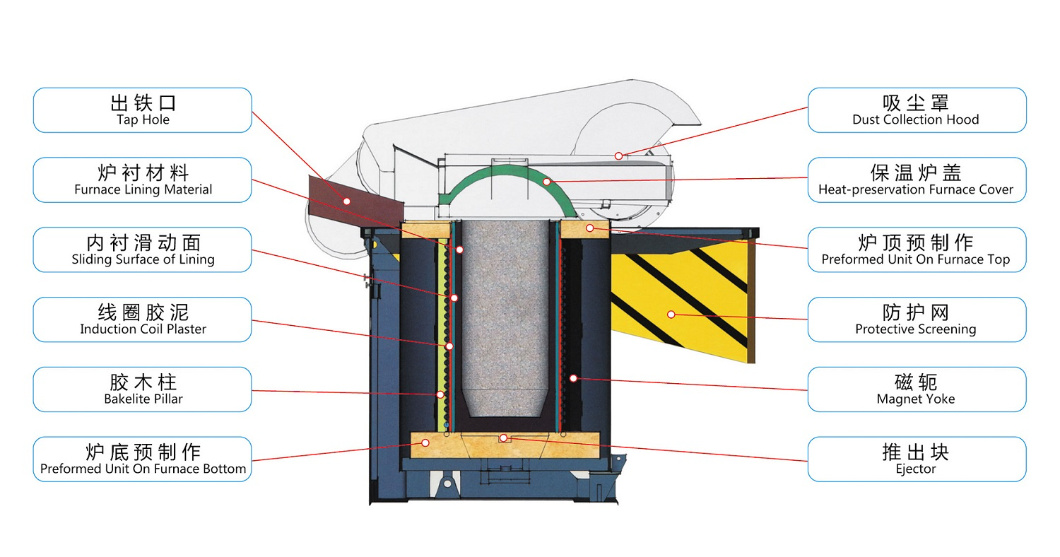

- Open furnace structure. The basic structure: with unique shock absorber and solid magnetic yoke, two cylinder with thick wall seamless rectangular steel tube is welded into one structure, being safer, firm, durable, high efficient. The upper end of the induction furnace can be disassembled to facilitate the replacement of the coil.

- Hydraulic tilting. Furnace can rotate around the pouring spout, and tilting with proportional control, through controlling buttons of hydraulic station and the handle of tilting control device . Its tilting angle is vertically at 95 degrees and it can stay in any position in the process of rotating, as well as to change titling speed to more quicker or more slowly. It uses the manual valve operation and double machine double pump, with remote manual control system. Some other company only have single pump control.

- Magnetic yoke. The sensor is enclosed with a magnetic yoke, covering an area is over 65%, so the leakage is small and achieve the maximum electrical efficiency. Compared with aluminum shell furnaces, steel shell furnace can save nearly 5% power consumption.

- Anti-fall protection device (for more than 2 ton capacity). During the process of tilting furnace, the anti-falling protective hood will be automatically raised to form a protective barrier to prevent the personnel from falling.

- Factory test.

Optional Feactures:

- Fume ring & fume hood. Dust ring and fume hood can absorb dust and exhaust gas generated during melting process through air. When working with dust removal system, they can reduce the exhausted gas emission, to meet the environmental requirements.

- Furnace leakage alarm. It is equipped with an alarm device for preventing furnace from leakage, which can achieve safe production. It is a special dual leak-proof furnace alarm, when the lining getting thinner to a certain degree, a warning light will be given to alert the user that the lining needed to rechanged.

- Push-out lining system to rechange the lining with a automatic and more efficient way.

- Load cells to determine the mass of the metal.Company introduction:

Established in 1999, Foshan Hengyang Furnace Manufacturing Co., Ltd is located in Foshan city, Guangdong Province, China, where is 20km from Guangzhou Baiyun International airport, so it has advantages of convenient transportation. As a hi-tech private enterprise, Foshan Hengyang Furnace Manufacturing Co., Ltd is one of the leading Chinese manufacturers of medium frequency induction furnace.

Have ofter-sale office abroad, and factory in Egypt.Exported to more than 30 countries and regions, such as Egypt, Algeria, South Africa, Uzbekistan, Kazakhstan, Malaysia, Indonesia, Russia, Mecigo, Tanzania, Saudi Arabia, Sudan, Zimbabwe, Korea, Vietuam, Bangladesh,USA, Portugal, Denmark, India, Pakistan, Iran, etc.